Product Description

The Robert Sorby Eccentric Chuck is the most sophisticated chuck for multi-centre turning.

Ease and accuracy of adjustment (without removing the workpiece from the chuck) is provided by the unique offset boss which accommodates the three different driving components on which to mount your workpieces, viz:-

- 1 - Screwchuck

- 2 - Ball drive and socket

- 3 - Faceplate

The Eccentric Chuck provides the means of driving from the headstock with or without tailstock support. The boss can be off-set incrementally by 11/4” (30mm) from zero datum point.

SCREWCHUCK:

The 25 x 10mm dia. parallel wood screw provides tremendous grip in either side-or end-grain. Requires an 8mm dia. pilot hole.

FACEPLATE:

An alternative method of attaching the work piece. Allowing the turner flexibility of approach. Ideal for larger work.

HEXAGONAL BALL AND SOCKET DRIVE:

A unique system for driving between centres. The hexagonal ball and socket unit allows the work piece to be angled within 20? of the lathe’s axis. Ideal for Cabriole legs. The socket component is flanged and drilled for attaching to the work but can also be repositioned to index a variety of polygon sections. Allowing eccentric turning at one end of the work blending into concentricity at the other.

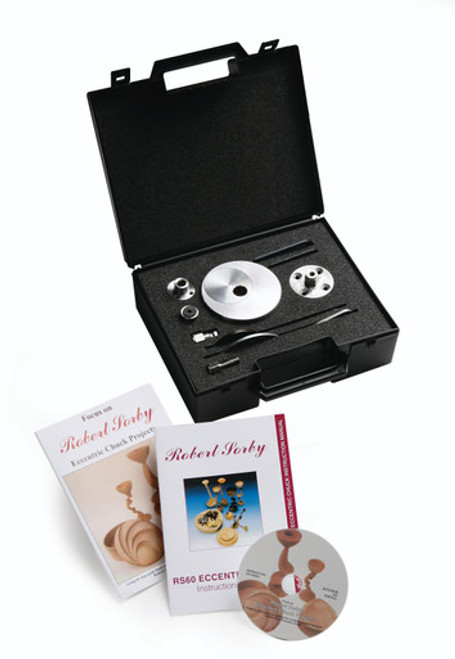

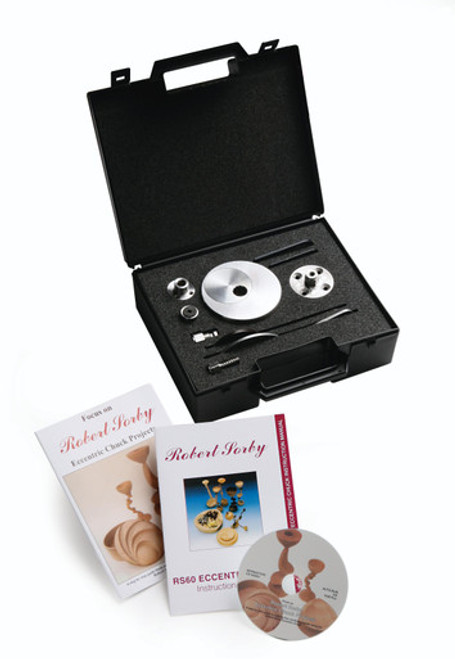

Full system housed in fitted, rigid plastic case for convenience and ease of storage. The Eccentric Chuck comes complete with a comprehensive 12-page instruction manual, interactive DVD and project book. It also includes a threaded adaptor to make it compatible with your lathe. The Eccentric Chuck is featured in our Decorative Techniques DVD (RSDVDDT) and the Thread Cutting and Eccentric Chuck DVD (RSDVDTCEC).

Threaded Adaptor included, size as specified in the description. Please check your lathe thread carefully before ordering, we are unable to accept returns on adaptors and lathe chucks.